|

NINGBO CRRCTIMES TRANSDUCER TECHNOLOGY CO.,LTD.

|

Rotation Speed Sensor

| Payment Terms: | T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Operating temperature: -25℃~+100℃

Speed measuring range:1000rpm~33000rpm

Signaling hole: 2×Φ4, depth 3 mm

TBT1A Rotation Speed Sensor

Application

TBT1A rotation speed sensor is a magnetoelectric rotation speed sensor, and it is installed t

the case or case cover of transmission gear, the tested rotary object is magnetic conductibility gea

which has two signaling hole with diameter 4 mm(depth 3 mm). It is composed o

permanent-magnet steel, electrical inductance coil, shell, shield cable, connector, etc. Outpu

signal is similar to sine wave, adapting operation with other speed measuring control equipment i

the various transport facilities. The sensor can detect the rotational speed of transmission gear an

the speed of transport, applicable to various transport facilities.

Features

Wide temperature accommodation

Wide speed measuring range

Strong shock resistance

Good tightness

Non-contact with tested gear, without abrasion

Convenient installation, simple and reliable

Main Technical data

Operating temperature: -25℃~+100℃

Speed measuring range:1000rpm~33000rpm

Signaling hole: 2×Φ4, depth 3 mm

Operating air gap: 1mm

Output waveform: Similar to sine wave

Output channel: 1

Coil resistance: 850?±10%

Output feature: Load resistance 10K? 0.5V≤Vp-p≤40V

Insulation resistance: ≥500M?(500V Megohmmeter)

Insulation strength: 500V/50Hz/60s

Output short-circuit protection: Available

2

Vibration and shock: Vibration 5.9 m/s ;Sh

Interface: QJ1-4BF1

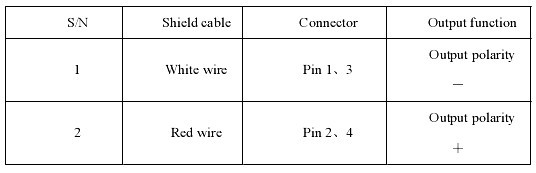

The definition of cable & connector output function

Installation\operation and malfunction disposal Forbidden contact between terminals; otherwise the permanent-magnet would be

demagnetized greatly, even damaged. Output wire distribution as per the definition strictly, and ensure it correct, without short

and open circuit; Strong recommend the air gap between gear and the head of sensor is adjusted to 1.0

mm,after adjusting the air gap, tighten these four fixed screws; When check the sensor, use the multimeter to measure DC resistance (connector pin1

and pin 3 or pin 2 and pin 4), the resistance should comply to 850?±10%, which shows the sensor

work normally.

Outline and installation drawing