|

NINGBO CRRCTIMES TRANSDUCER TECHNOLOGY CO.,LTD.

|

Speed Sensor

| Payment Terms: | T/T,T/T |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Installation\operation and malfunction disposal We have already considered the terminal protection during the ex-work package of the se

TQG19G Speed Sensor

Application

TQG19G speed sensor is a double-channel Hall speed sensor, and it is installed to the case or case

cover of transmission gear, the tested rotary object is magnetic conductibility gear whose module is equal

to 2.75. It is composed of permanent-magnet steel, magnetic energy converter, amplifier shaping circuit,

shell, shield cable, connector, etc. Output signal is square wave, adapting operation with other speed

measuring control equipment in the various transport facilities. The sensor can detect the rotational speed

of slewing gear and the speed of transport and communication facilities, applicable to various transport

facilities.

Features

Wide temperature accommodation

Wide speed measuring range

Strong shock resistance

Good tightness

Non-contact with tested gear, without abrasion

Convenient installation, simple and reliable

Main Technical data

Operating temperature: -40℃~+100℃

Supply voltage: 10VDC~30VDC

Frequency range: 0Hz~20KHz

Air gap: 0.1mm~1.5mm,Standard installation value:0.8mm

Gear: m=2,number of teeth z=60,material: magnetic mild steel

Output waveform: Square wave

Output channels: 2

Output voltage range (load =3 K?):High level VH≥Vcc-2.5V,low level VL≤1.5V;

Pulse duty cycle: 50%±20%

Phase difference: 90°±30°

Current consumption without load:≤60mA

Insulation resistance: ≥50M?(500V megameter)

Dielectric strength: 1000VAC/50Hz/60s

Polarity protection: yes

Short circuit protection: yes

Vibration and shock: Vibration: 30g;Shock:: 100g

Electric interface: Cable lead

The definition of cable & connector output function

| S/N | Shielding cable | Output function |

| 1 | Brown wire | Power supply Vcc |

| 2 | Green wire | Power supply GND |

| 3 | Blue wire | Signal channel 1 |

| 4 | White wire | Signal channel 2 |

| 5 | Black wire | Shield |

Installation\operation and malfunction disposal

We have already considered the terminal protection during the ex-work package of the sensor,

please take out the protecting cover when installation, and install the protecting cover when not

using the sensor; Forbidden contact between terminals; Output wire distribution as per the definition strictly, and ensure it correct, without short and

open circuit; Strong recommend the air gap between gear and the head of sensor is adjusted to 0.8mm,after

adjusting the air gap, tighten these two fixed screws; Before the sensor not installed to speed measuring end cover, power connection, use

ferromagnetic slice to contact or leave the head of sensor, if there are high or low level changes,

which means normal; At normal operation, there are no change of sensor output level (high or low), which means the

sensor is damaged. Disposal method: change the sensor.

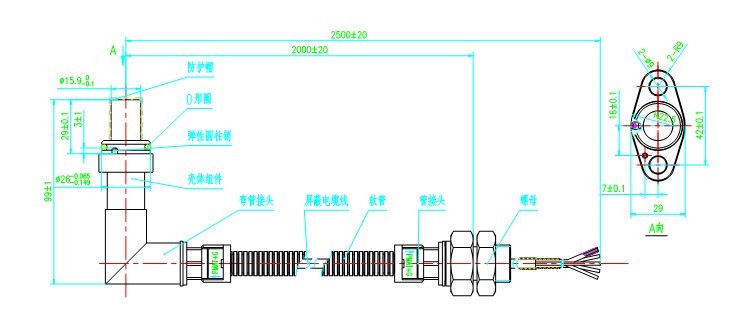

Outline and installation drawing